Copper Sheathed & Copper Clad Hull Anode Fitting Instructions

Back

Fitting Instructions

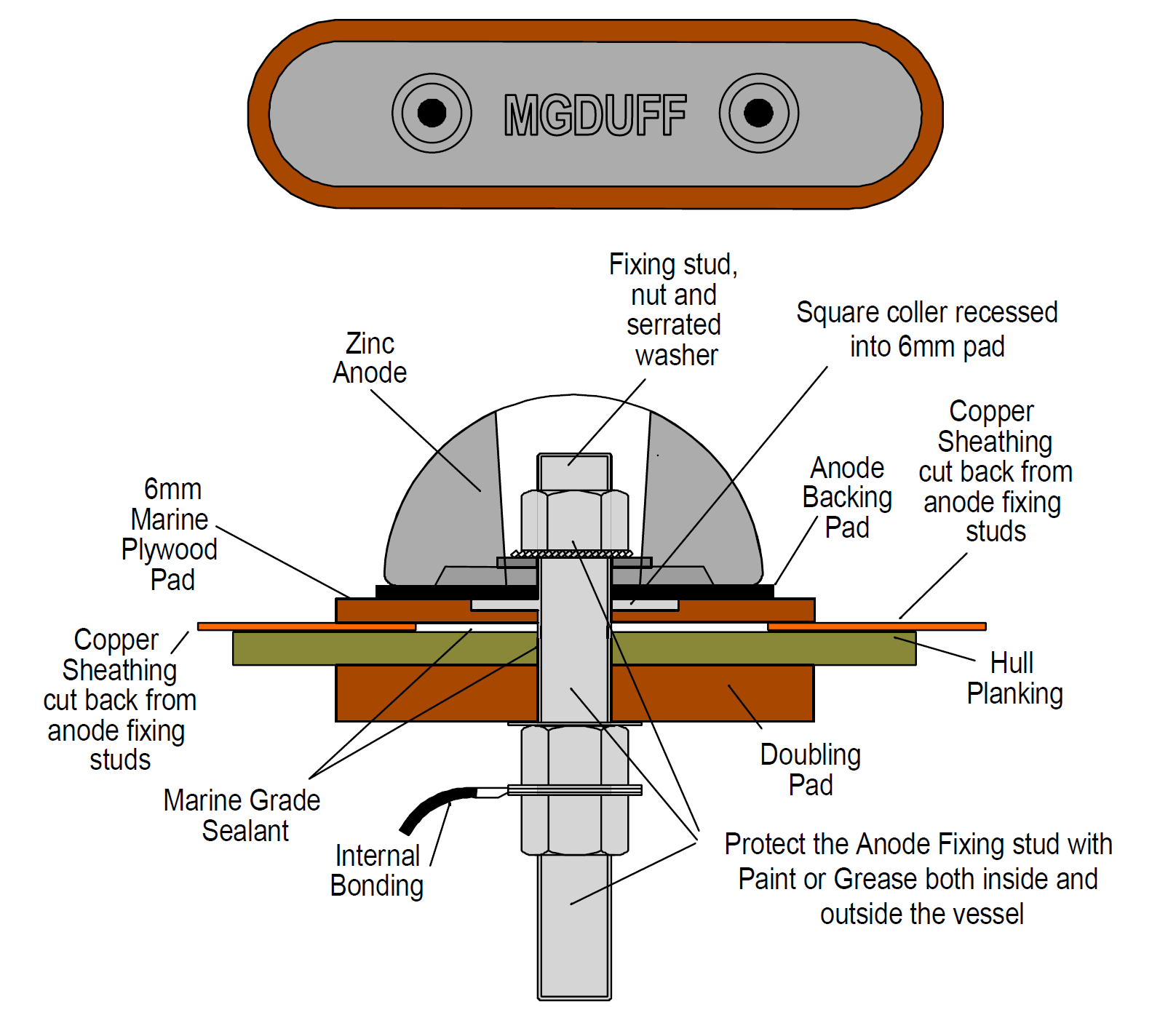

- The copper must be cut back to 20mm clear of the anode fixing studs collars.

- A pad of 6mm thick marine plywood is to be fitted between the rubberised anode backing sheet and the copper sheathing. The pad must be painted with an epoxy resin paint system or similar and is to be well bedded with marine grade sealant. The pad should extend at least 15mm clear of the anode and over the area where the copper has been cut back clear of the studs.

- The copper must not be allowed to be in contact with any metal work which is being cathodically protected. The copper must be cut back from the outer end of the stern tube and any other metal fittings that are bonded into the cathodic protection system e.g. shaft brackets rudder bearings and glands if these are to be protected. It is advisable to check that the cathodic protection system is isolated from the copper using a suitable multi-meter.

- Where the copper has been cut back areas of exposed hull especially wooden hulls should be well painted with an appropriate epoxy resin paint system or similar.

- Metallic based anti-fouling must not be used on the plywood pad or on the areas where the copper has been cut back.

- When selecting the correct anode for your boat please refer to our brochure.